Breakaway Lanyard Safety Basics for Workplaces: Hardware, Policy, and Maintenance

Why a breakaway lanyard is a workplace safety essential

A breakaway lanyard is built with a connector that separates under a set amount of force. In day-to-day terms, it’s designed to “give” if your badge gets snagged on something like a door handle, a cart, shelving, or equipment—helping reduce choking or entanglement risk while employees still wear visible identification. That matters in workplaces that rely on worn ID for security checks, visitor management, access control, or quick recognition of who belongs in an area. The goal isn’t to stop people from wearing badges; it’s to support identification in a way that better matches real movement and real hazards. The key expectation to set internally: breakaway hardware is a practical safeguard for routine ID wearing. It reduces foreseeable risks that come from the lanyard itself, especially in busy or equipment-heavy environments.

Visible IDs can support security and trust, and breakaway hardware helps keep that practice compatible with everyday workplace movement.

How breakaway hardware works (and what it does not do)

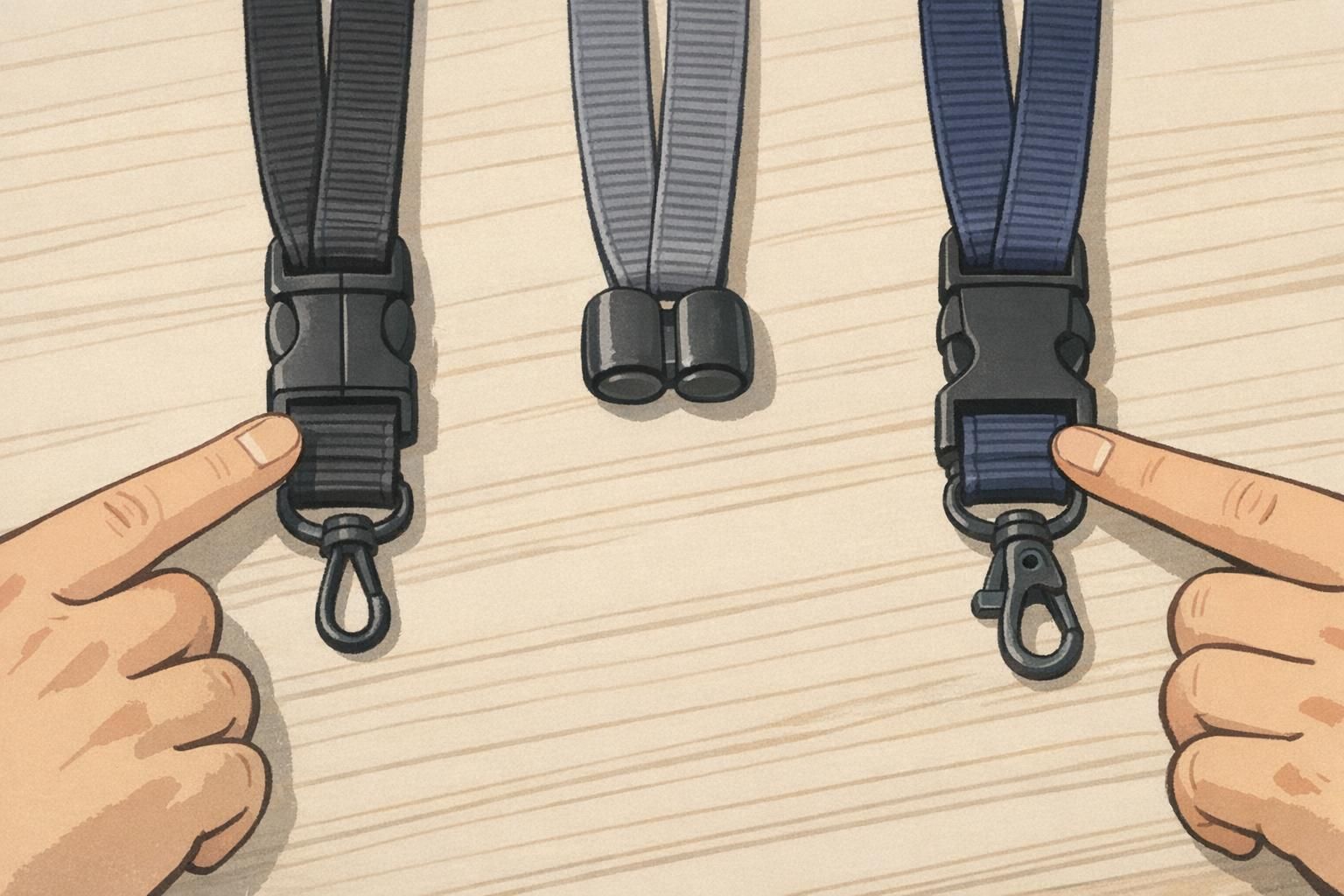

Breakaway features are typically built into the lanyard near the back of the neck. If the lanyard is pulled or caught, that connector is intended to separate before the force transfers to the wearer’s neck. Common breakaway mechanisms include: 1) Plastic breakaway clasp: Often a two-piece plastic connector that snaps together and pulls apart under force. 2) Magnetic breakaway: Uses magnets that separate when tugged; some people prefer the smoother re-connection. 3) Hook-and-loop style breakaway: Less common as a dedicated “clasp,” but the principle is similar—there’s a deliberate release point designed to separate when pulled. You’ll also hear the phrase “breakaway force.” Practically, that means the connector is designed to release only after a certain tug—strong enough for normal wear, but intended to separate if snagged. Because every workplace has different hazards and different lanyard designs, the most important part is consistency: choose a style you can standardize, then maintain and inspect it so it releases as intended. What a breakaway feature does not do: it does not turn an ID lanyard into fall protection. ID breakaway connectors are aimed at reducing entanglement and choking risk from an ID badge system. They are not a substitute for jobsite PPE, harnesses, or certified energy-absorbing fall arrest components. Work-at-height systems require the correct certified equipment and careful planning, including adequate clearance distance and component compatibility. For a neutral overview of why clearance and system design matter in work-at-height lanyard use, see this discussion of lanyard clearance calculations and related considerations: source.

- Breakaway connectors can change behavior over time: wear, cracking, and stretched material can affect whether (and how) they release.

- Typical failure points include: worn clasp edges, cracked plastic, stretched cord, frayed fabric, or damaged stitching near the connector.

- If a breakaway connector starts releasing too easily (or not releasing when tugged), treat it as a replacement item rather than a “keep using it” item.

Workplaces that should require breakaway lanyards

If your workplace requires badges to be worn visibly, the question becomes: where could a lanyard realistically get caught, pulled, or grabbed? A risk-based approach keeps the rule simple: require breakaway lanyards anywhere snagging is more likely or where people move quickly through tight spaces. Environments that commonly benefit from requiring breakaway hardware include manufacturing lines, warehouses, maintenance shops, labs, food processing areas, schools (especially busy corridors and playground duty), hospitals, and any site with rotating equipment or frequent doorway traffic. It’s not only the environment—it’s the tasks. Roles that lean over machinery, use carts frequently, work in crowded hallways, or work around patients/students (who may grab a lanyard) are also good candidates. This is the practical bridge between identification and hazard control: you can keep IDs visible and easy to verify while lowering the chance that the lanyard becomes the weak point in an otherwise good safety routine.

- Rotating or moving equipment nearby (even if guarded)

- Frequent use of carts, pallet jacks, or rolling bins in narrow aisles

- High doorway traffic where lanyards can catch on handles or corners

- Hands-on work that requires leaning forward or reaching into tight spaces

- Work around children, patients, or the public where grabbing is possible

- Areas with frequent PPE changes (lanyards can snag during doffing/donning if worn under layers)

Requiring visible badges and requiring breakaway connectors are not competing goals. In many workplaces, they’re the best way to make ID rules workable and safer.

Creating a badge lanyard policy that’s simple and enforceable

A badge lanyard policy works best when it’s short, specific, and easy to observe. People should be able to look at a coworker and quickly tell whether the rule is being followed. Below is plain-language policy wording many organizations can adapt. The aim is consistent identification (badges stay visible) while reducing foreseeable snag hazards (lanyards release appropriately). This also supports consistent visitor management, because visitors tend to copy employee behavior.

- Breakaway requirement: Employees, contractors, and onsite vendors must wear a breakaway lanyard in designated areas (and/or whenever a lanyard is worn onsite).

- Wear position: Badges must be worn outside clothing and hang at mid-chest, facing forward, so they are easy to verify without handling.

- Approved attachments: Only approved badge attachments are allowed (for example, swivel hook, bulldog clip, or holder attachment that keeps the badge flat).

- Snag-risk add-ons: Do not add long accessories or extensions that increase length or snag potential.

- Area-based restrictions: In certain areas, metal chains or heavy hardware may be prohibited; use fabric lanyards or clip-only options as assigned.

- Task-based alternatives: For specific tasks where a lanyard creates a higher snag risk, a clip-only option may be required for the duration of the task (then return to standard wear after).

- Visitor and event consistency: Visitors and temporary staff must follow the same breakaway requirement when issued a lanyard-style badge.

- Security coordination: Badges must remain visible and readable; do not tuck badges into pockets or turn them around to avoid display.

“If someone has to touch or flip a badge to verify it, we’ve already created extra interaction and extra risk. A clear, consistently worn badge is safer and more professional.” – Facilities Supervisor

Choosing the right lanyard for comfort, visibility, and compliance

Comfort and compliance are closely linked: if a lanyard is itchy, too long, or constantly twisting, people will improvise (tucking it in, wrapping it, clipping it to something else). Choosing designs by role helps keep ID requirements realistic. Material options: Flat polyester: Common, comfortable, and typically lays flatter for readability. Tubular: Softer feel and can be comfortable for all-day wear. Braided cord: Often lighter, but may roll and twist more, which can reduce consistent badge visibility. Attachment options: Swivel hooks: Reduce twisting and make it easier for the badge to face forward. Bulldog clips: Useful when you need to grip a badge or holder firmly. Detachable buckles: Helpful for quick removal of the badge portion without taking the lanyard fully off (useful for scanning, swapping holders, or controlled access points). Role-based selection examples: High-movement jobs: Consider shorter lengths, stable attachments, and a setup that keeps the badge from swinging into equipment. Front desk or customer-facing roles: Prioritize clear visibility, brand consistency, and a holder that keeps the badge flat and readable. One universal safety detail: ensure the breakaway connector is positioned behind the neck. That placement supports consistent release behavior and keeps the front of the lanyard simpler and more comfortable.

A good lanyard fit is a safety feature: mid-chest placement and a stable attachment reduce swinging, fumbling, and snag opportunities.

Maintenance and inspection tips (what to check weekly)

Lanyard safety depends on the connector behaving predictably. A simple weekly check is usually enough to catch wear before it becomes a problem. Keep the routine quick so it actually happens. A practical inspection routine: 1) Test the breakaway: Gently tug to confirm it opens as intended, then re-close it to confirm it clicks (or connects) securely. 2) Look for damage: Check for cracks in plastic, fraying fabric, stretched material, or loose stitching near the breakaway point. 3) Check the attachment: Look for sharp edges, corrosion, or bending on hooks and clips. 4) Confirm comfort and position: Make sure it still hangs mid-chest without excessive length or swinging. Replacement triggers (swap it out): Cracking, inconsistent release, connectors that won’t stay closed, connectors that release too easily during normal wear, deformed clips, or any sharp edges. Cleaning: For most workplaces, light soap and water and air drying is a practical baseline. In healthcare, labs, or regulated environments, follow facility cleaning rules so the lanyard and holder don’t become a contamination concern. Operational tip: keep spare breakaway lanyards available so a damaged one can be replaced immediately without interrupting ID compliance.

- Weekly: quick tug-test the connector and visually check for cracks or fraying

- After incidents: replace any lanyard that was snagged hard or involved in a pull event

- When in doubt: swap it—lanyards are wear items, and predictability is the goal

Training and day-to-day behaviors that improve lanyard safety

Even the right hardware benefits from simple habits. Training should focus on the small behaviors that prevent snagging and keep badges readable without extra handling. Good day-to-day behaviors to train: Wear it outside clothing so the badge stays visible and doesn’t catch during layer changes. Don’t wrap a lanyard around your wrist, tool handle, or bag strap. Avoid attaching keys, tools, or heavy items—extra weight increases swing and snag potential. Report damaged connectors immediately and replace instead of improvising. Supervisor-friendly reminders that work well in onboarding and huddles: Show what “mid-chest” looks like in your environment. Point out where the breakaway sits (behind the neck) and why. Normalize quick inspections: “tug-test before task start” in higher-snag areas. When these habits are consistent, workplace identification stays clear and professional while the lanyard itself is less likely to become a hazard.

ID presentation upgrades that support safety and clarity (BadgeZoo products)

Breakaway connectors address the “snag and pull” risk, but day-to-day usability also depends on how the badge is carried. A clear badge holder keeps the ID protected, readable, and less likely to flip or bend—so employees and visitors don’t have to fidget with it to be verified. Pairing breakaway lanyards with a holder can also support lanyard safety by keeping the badge stable and reducing repeated handling near doors, checkpoints, or patient areas. A straightforward option is a clear vertical ID badge holder, which helps keep the card surface protected and the badge facing forward for quick checks. In areas where scanning is common, a holder that keeps barcodes and printed details from wearing down can reduce reprints and day-to-day frustration. If your policy requires different attachments by area (for example, clip-only alternatives for certain tasks), choose holders and attachment points that match those rules so employees aren’t forced into workarounds.

A stable, readable badge setup reduces “badge handling,” which helps verification stay quick and keeps hands away from moving through-door traffic and equipment areas.

Quick FAQ: breakaway strength, visitors, and special job tasks

Look for a dedicated connector designed to separate under force, typically positioned behind the neck. If you can’t identify a release point, or if the connector is purely decorative, it may not provide breakaway behavior. Standardize approved models and include a simple tug-test in your weekly check.

A reel can be a good alternative in some roles because it reduces hanging length and swinging. For higher-snag tasks or areas, a clip-and-reel setup may be the safer choice. The best approach is to define acceptable options in your badge lanyard policy by task and area, so employees aren’t guessing.

If visitors are issued lanyards, issue breakaway lanyards so the rules are consistent and the risk is reduced. Keep the visitor badge clearly visible and easy to verify to support access control and reduce confusion.

Yes. Branding and safety can coexist as long as the lanyard includes functional breakaway hardware, is an appropriate length for the environment, and is worn correctly (mid-chest, outside clothing). Standardizing the breakaway connector style and inspection routine usually matters more than color or design.

Use task-based alternatives (such as clip-only wear) for the duration of the task, then return to standard wear afterward. Identify these tasks in advance with supervisors so the option is clear and consistent, and make sure IDs remain visible and easy to verify when the task allows.

The strongest programs treat breakaway lanyards as part of everyday lanyard safety: clear rules, consistent wear, weekly checks, and simple alternatives for special tasks.